Over 30 years of maximum precision in SMT manufacturing

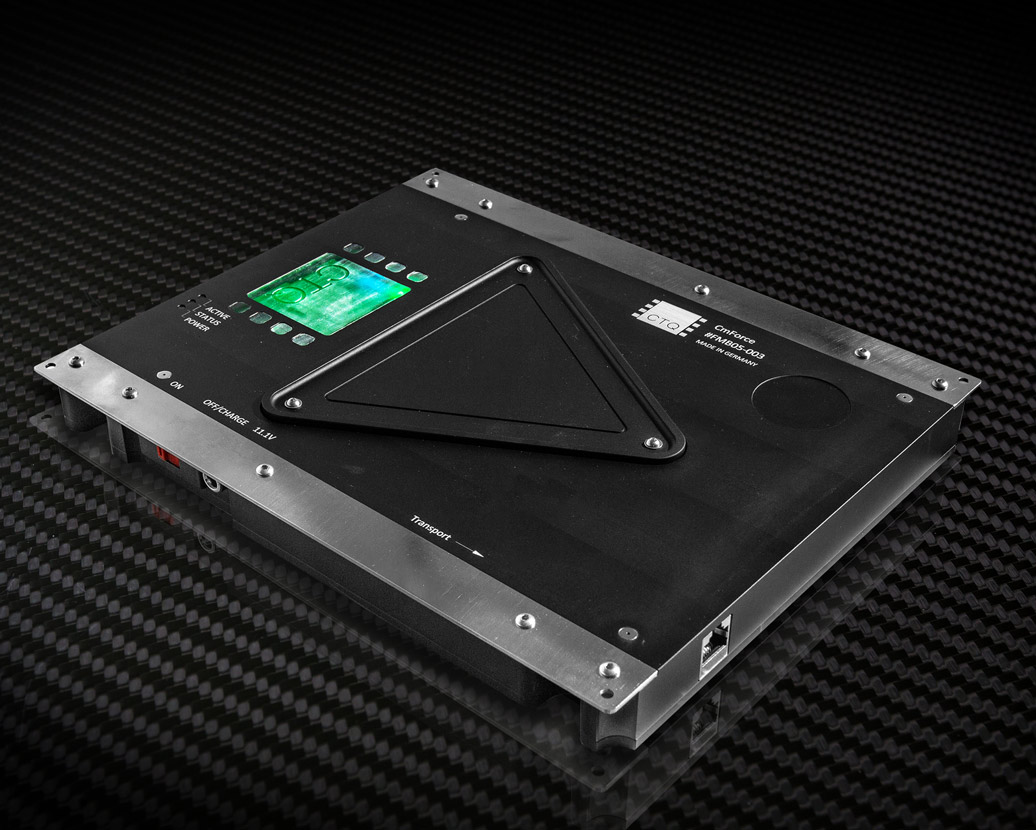

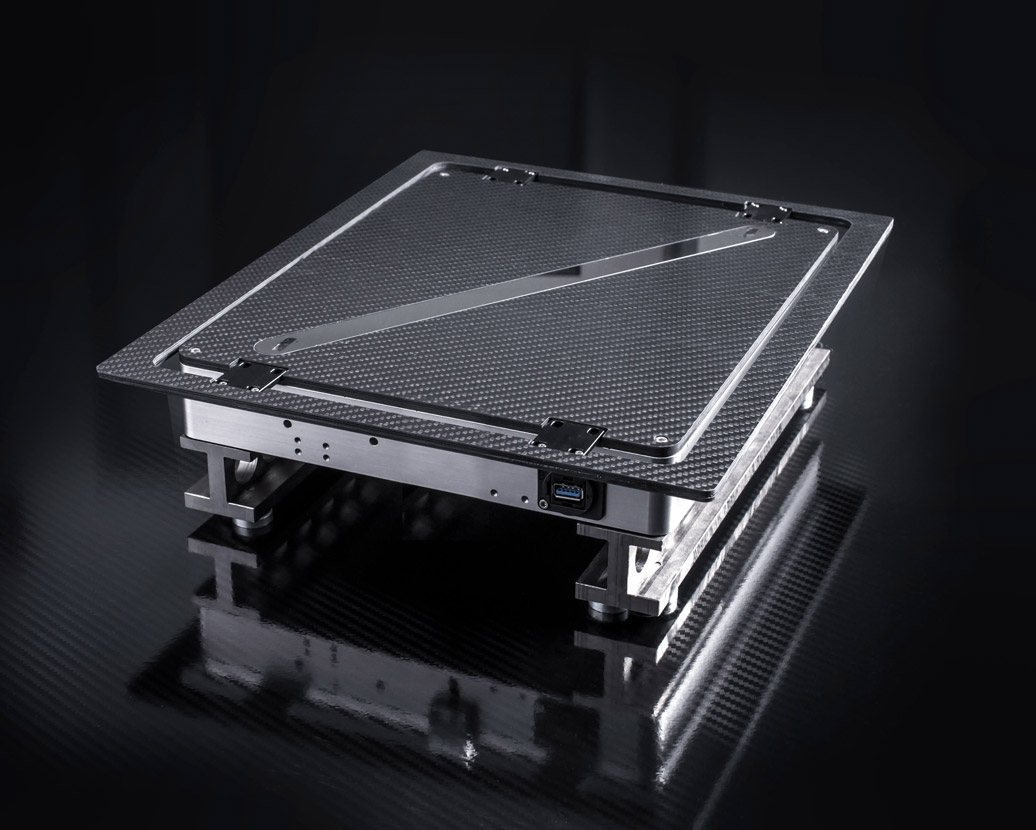

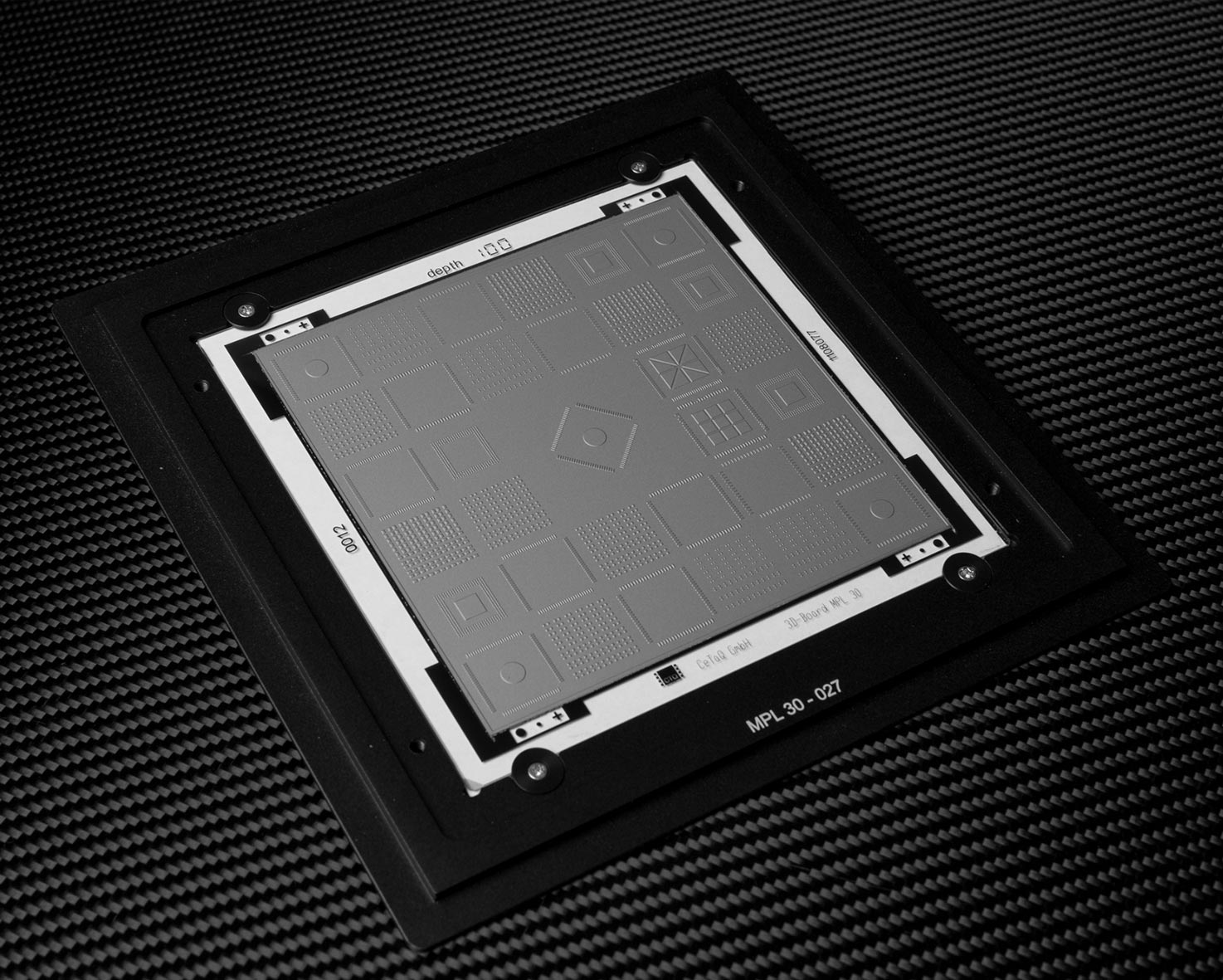

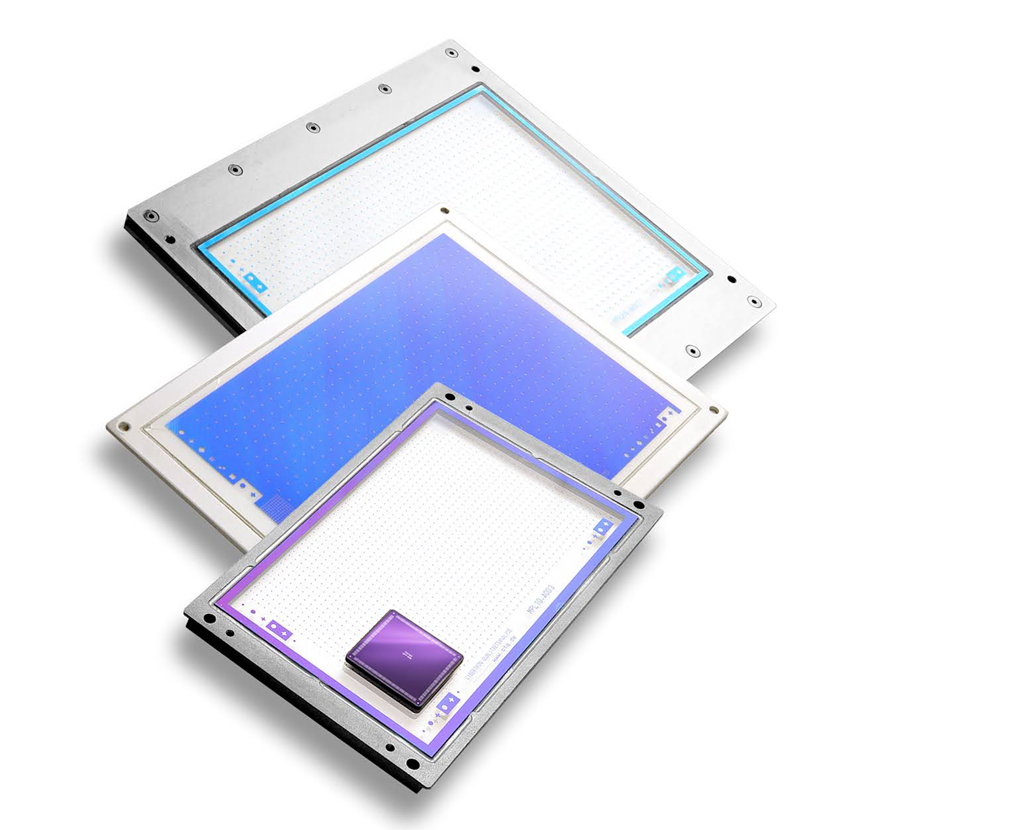

CeTaQ GmbH specializes in manufacturer-independent MFU and process optimization in electronics manufacturing.

Our customers worldwide benefit from profound expertise, state-of-the-art measurement technology, and a team that prioritizes precision and quality.

Thanks to our many years of experience in SMT manufacturing, we are able to objectively analyze complex manufacturing processes and optimize them in a targeted manner. We operate independently of manufacturers to always deliver neutral and reliable results.